2K wet paint from Brillux Industrial Coatings at Hammelmann GmbH Getting better and better under pressure

Lots of water, often UV radiation and harsh operating conditions too: the painted surfaces of Hammelmann products must be able to withstand all adversities. The manufacturer of high-pressure systems relies on constant process optimization and 2K wet paint systems from Brillux Industrial Coatings for the surface quality. Hammelmann recently used its expertise to integrate a new mixing and dosing technology into the production process.

Hammelmann GmbH, based in Oelde in Westphalia, Germany, has the most innovative, sustainable and functional solutions when it comes to stripping paint under high pressure, cleaning with water jet technology, removing, deburring, derusting or cutting. “For 75 years, Hammelmann has been the driving force behind the development of high-pressure pumps and systems for almost every industry around the globe,” explains Jascha Kolter, Head of Marketing at Hammelmann.

The medium-sized manufacturer and technology leader is growing, employs 650 people worldwide and is represented by subsidiaries worldwide. Ten years ago, Hammelmann GmbH invested heavily in the Oelde-based parent plant and created a state-of-the-art production site. But Hammelmann does not rest on its successful market position. Ongoing process optimizations are part of the DNA of the high-pressure specialists – right down to the coating technology.

Single-layer finish with strong performance

“Our customers expect quality, durability, high efficiency and a long service life from our products - regardless of whether they use our pumps in manufacturing, construction or mining, in shipbuilding, offshore or in the food industry,” says Kolter. “The uncompromising quality of our product coatings plays a role here,” adds Stefan Wickenkamp, Head of Steel Construction and Paint Shop at Hammelmann. “Quality features such as optimum corrosion protection and durability are essential for us.”

Since 2018, the company has gained the best experience for the C2 coatings in the factory standard with the weather-resistant, UV-stable 2K-PUR High Solid Paint 5730 in the gloss grades smooth and high gloss from Brillux Industrial Coatings. The high-solids polyurethane coating provides the desired excellent corrosion protection and very good resistance to mechanical and chemical influences. As a result, the products with their highly resistant surfaces are not only able to assert themselves in the robust areas of application. In addition, thanks to their high yield, noticeable efficiency gains are already achieved during the painting process. Stefan Wickenkamp: “We mainly process this VOC-reduced wet paint in a single coat. In this way, we shorten lead times and save paint material and emissions.”

Ideally adjusted for demanding application

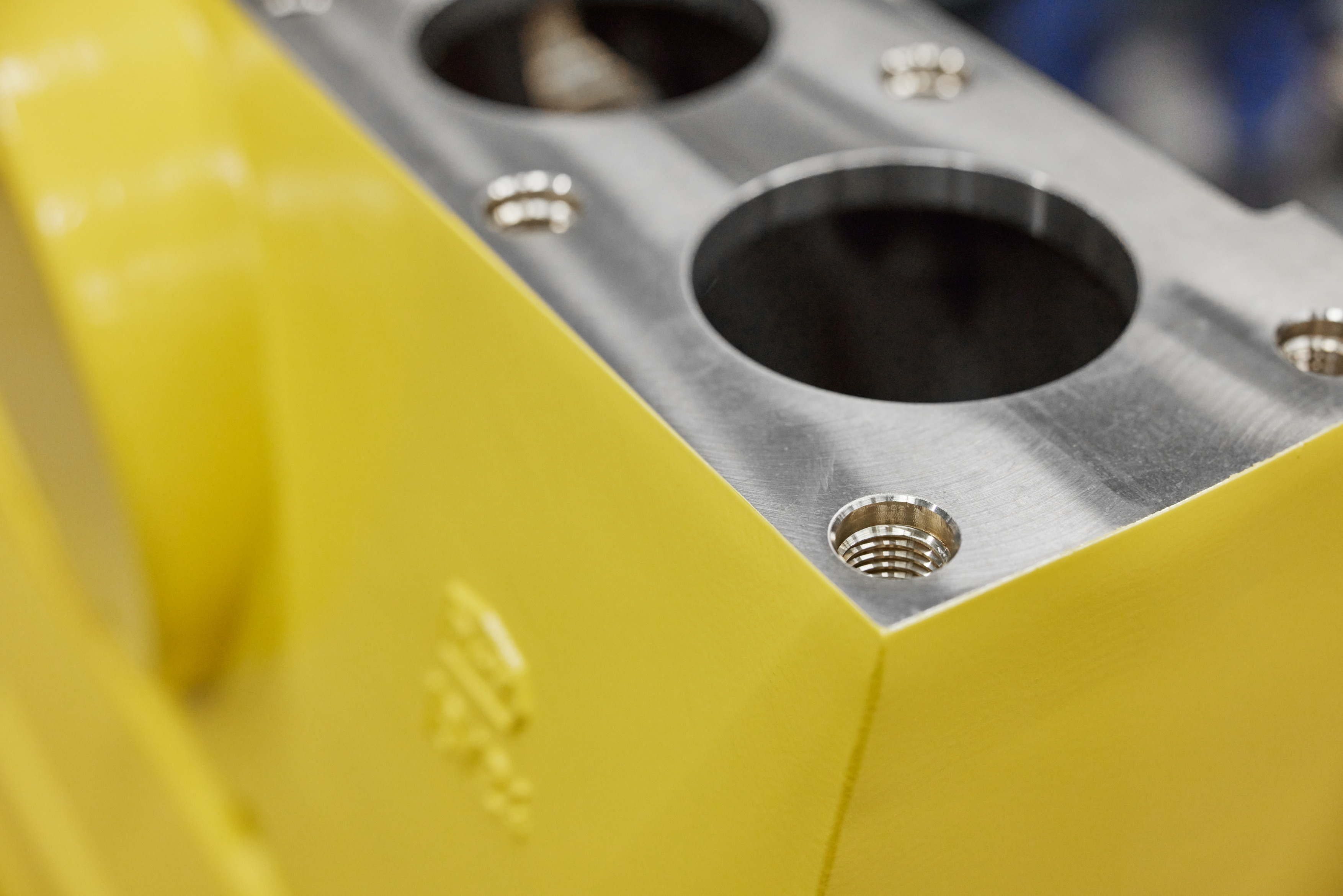

The Oelde-based company was also impressed by the unusually good applicability of the 2K-PUR High Solid Paint 5730 - both when applied with a low-pressure cup gun and using the electrostatic method. It meets the company’s high quality standards and efficient work processes. “Our products often have complex geometries,” explains Stefan Wickenkamp. “That's why the ease of application, even in hard-to-reach areas, as well as the good coverage and stability of the coating with a low edge alignment effect are essential for us.”

Together with Marvin Dropmann, Technical Consultant at Brillux Industrial Coatings in Unna, the Hammelmann paint shop has optimized the recipe of the wet paint to meet its special requirements in terms of durability and spray mist absorption and is continuously improving it. “We regularly share our experiences and current challenges on site, including with the painters, and adjust every detail accordingly,” emphasizes Dropmann. This ongoing focus on adjusting to find the best possible paints, which is supported by Brillux R&D for Wet Coatings with its own services under one roof, recently paid off when the company switched from a manual to an efficiency-enhancing electronic mixing and dosing system, emphasizes Wickenkamp: “The coating product was so perfectly adjusted that we were able to continue working with it without making any changes.”

Wide range of color shades with optimum fine adjustment

Even if functional aspects play the main role in the surfaces of Hammelmann products, customers in various industries require special visual qualities when fitting out their pumps. “We naturally cater to special color requests,” says Stefan Wickenkamp. “The 2K-PUR-High-Solid Paint 5730 offers us all possibilities beyond the standard.” With the Brillux wet paint, Hammelmann produces not only the house colors in RAL 7043 and 1018, but also Munsell color shades, for example.

“The fact that this does not mean any additional expenditure for Brillux Industrial Coatings and that we are able to act at any time thanks to the fast delivery within 24 hours is one of the other plus points,” says Wickenkamp. Two different Brillux hardeners are used to fine-tune the different color tones. “Our standard PUR Hardener 5770.-.10 delivers excellent results for most color shades,” explains Dropmann. “With demanding Munsell colors, we support the stability with the short curing time of the quick-drying PUR Hardener 5770.-.70.”

Only better is good

The journey towards even more economical coating processes while maintaining the highest quality standards continues in the Hammelmann GmbH paint shop. “The next step will be to better bundle the processed shades in the process in order to reduce the number of color changes and thus realize further time-saving potential,” announces Stefan Wickenkamp.

If coating-related issues arise again in future optimization projects, Wickenkamp knows that he can rely on Brillux Industrial Coatings: “The proximity to the manufacturer and the personal support guarantee us fast and sustainable solutions that meet our speed and our requirements.”

Hammelmann GmbH

Hammelmann has been the market-leading supplier of high-pressure pumps and technical systems for high-pressure applications for over 70 years.