High-caliber expert meeting at Brillux Industrial Coatings Powder coating solutions for defense technology

More than 80 selected decision-makers from the technical fields of the German Armed Forces, industry and coating services met in Münster to obtain detailed information on powder coating solutions for military technology and to engage in a lively exchange of ideas. Brillux Industrial Coatings invited to the fully booked one-day event.

The requirements for surface coatings in the military sector are highly specialized. In addition to the tried-and-tested wet paints, powder coating systems are also coming into focus in this field due to their outstanding technical performance and economic advantages. What opportunities are opening up with these surface coatings? What can and must these products do? What concrete experience has already been gained in coating practice and in switching from wet to powder coating systems? This comprehensive perspective of the information and discussion event "Powder coating solutions for defense technology" organized by Brillux Industrial Coatings was met with a great response from the high-caliber audience.

Expert knowledge with high practical relevance

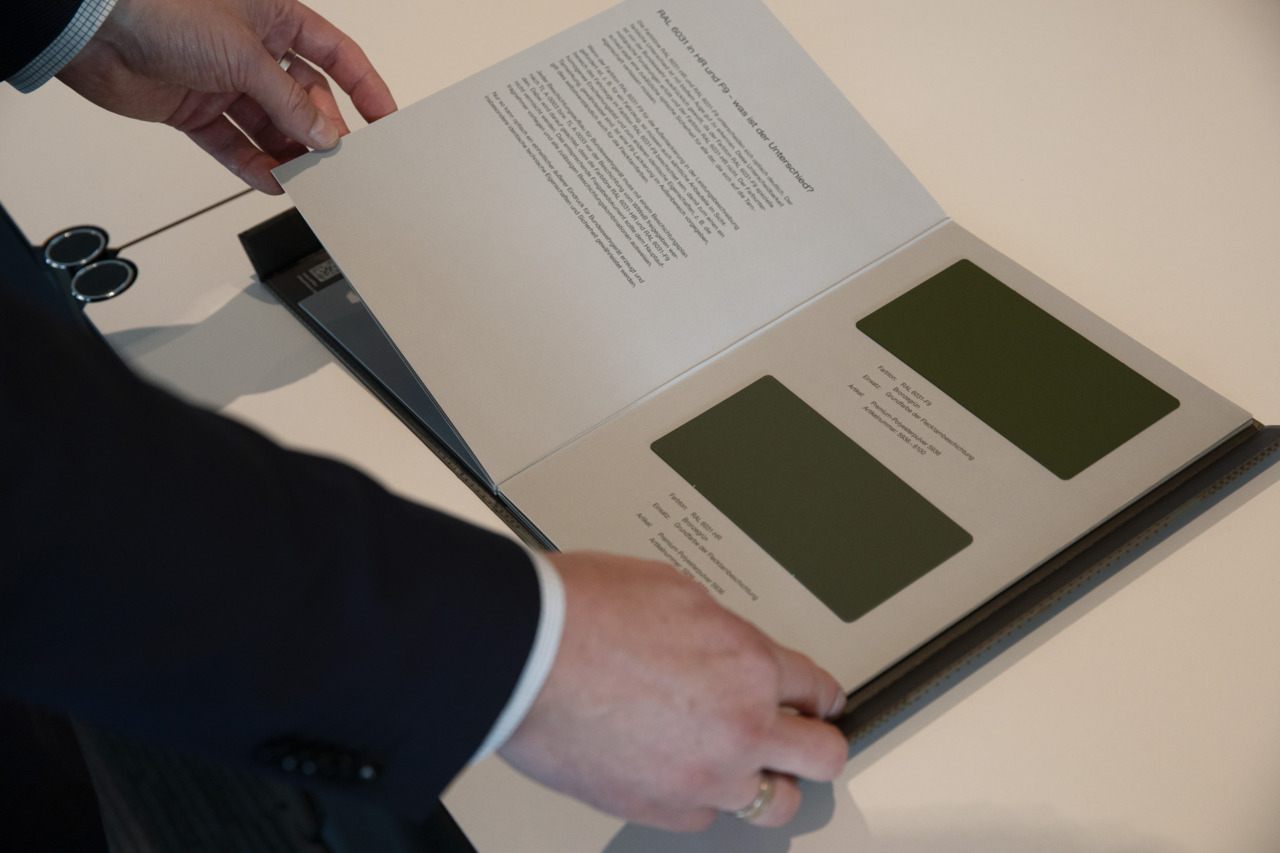

The speaker from the Wehrwissenschaftliches Institut für Werk- und Betriebsstoffe (WIWeB) gave the participants a first-hand account of how intensively and with what time horizon the institute tests coating systems with a detailed catalog of requirements – including the resistance of the entire coating structure to explosive ordnance. This became tangible in the second presentation. The powder coating system certified by WIWeB for its coating properties in accordance with RAL-F9 specifications is the highly weather-resistant Brillux Premium Polyester Powder 5936. The specially adapted formulation achieves an excellent camouflage effect in the visible and near-infrared spectral range. This way surfaces can be created that are even hidden from infrared night-vision devices.

Brillux Premium Polyester Powder 5936 with F9 approval is available in all four relevant shades required for military coatings for the German Armed Forces. Attendees were eager to learn about applications where powder coatings can be used to deliver measurable environmental and economic benefits: their use ensures short process throughput times, minimizes material consumption and leads to permanent VOC reduction to zero. Equally valuable was the overview of BAFA export licensing procedures, as F9 quality powder coatings are classified as military equipment. Practical examples from coating companies that are already successfully processing powder coating systems for military equipment of the German Federal Armed Forces rounded off the event’s agenda.

A very welcome opportunity for exchange

The panel discussion emphasized the importance of communication between major defense contractors, coating service providers and developers and producers of advanced powder coating systems for defense technology. During the breaks, the participants, some of whom had traveled long distances, took advantage of the rare opportunity for personal exchange and networking: It was the first, but certainly not the last Brillux Expert Forum for the decision-makers and coating professionals of this specialized industry.